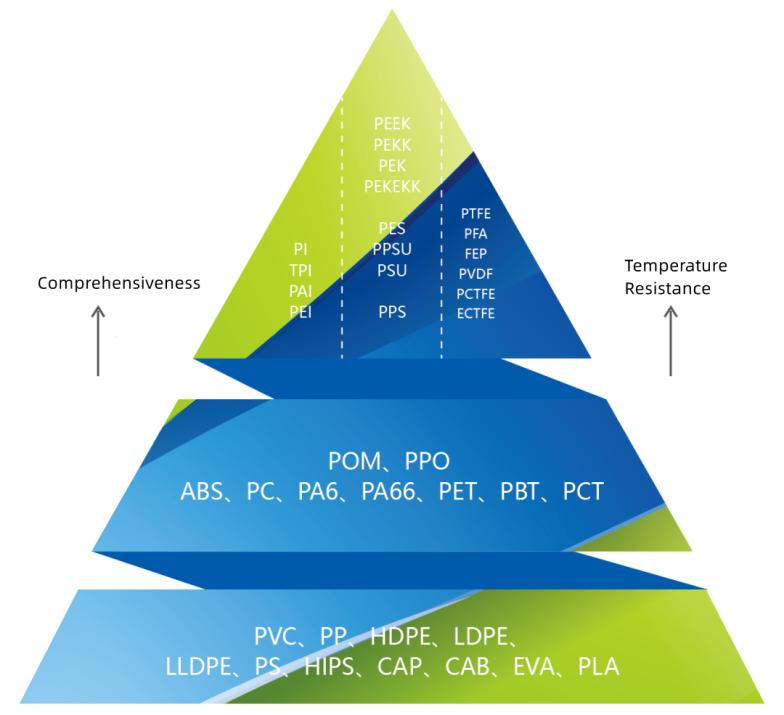

M'zaka zaposachedwa, kugwiritsa ntchito mapulasitikisi apadera apadera kwapita ku minda yankhondo yakale ndi a Aerospace kupita m'minda yambiri yakale, monga magalimoto, kupanga zida zapamwamba, komanso katundu wothamanga kwambiri. Pakati pawo, polyphenynene sulfide (PPS) ndi Polytheretherone (peek) ndi mitundu iwiri ya mapulasitikisi apadera omwe ali ndi chitukuko chachangu.

Peek ndi wamkulu kuposa ma pps malinga ndi mphamvu, mphamvu, komanso kutentha kwambiri. Pankhani ya kutentha kwambiri, kutentha kwa kutentha kwa peek kukana ndi pafupifupi 50 ° C okwera kuposa ma pps. Kumbali inayo, phindu lodziwikiratu komanso mwayi wabwino wokonza ma pps zimagwiritsidwa ntchito kwambiri.

PPS ili ndi maubwino otsatirawa:

(1) Tormeic Flameal

Different from PC and PA, PPS pure resin and its glass fiber/mineral powder filled composites can easily achieve V-0 @ 0.8mm or even thinner thickness V-0 flame retardant without adding any flame retardant level. Although PC and PA have cheaper prices and better mechanical strength (especially impact strength) than PPS, the cost of PC and PA composites with halogen-free flame retardant formulations (V-0@0.8mm level) is higher than that of PPS. It will rise sharply, and in many cases even higher than PPS materials with the same mechanical strength.

(2) Ultra-Intrity

Mu gawo la pulogalamu ya chivundikiro chophimba, mwayiwu ndi wowonekera kwambiri kuposa wa PC. Kuchuluka kwapamwamba sikungosokoneza madzi ndi kumapangitsa mavuto, komanso kumayambitsa mavuto, komanso kumayambitsa mavuto, komanso kumayambitsa mavuto, komanso kumayambitsa mavuto, komanso kumayambitsa mavuto, komanso kumayambitsa mavuto, komanso kuchititsa mavuto monga pansi ngati ulusi, ndi mphamvu zosauka. Kwa Semu-Crystalline PPS, madzi ake okwera kwambiri amalola kuti zitsamba zodzaza ndi zokwanira 50%. Nthawi yomweyo, mu njira yotentha yosungunula kuphatikiza ndi kupendekeka, kukweza kwa PC kumatha kupanga ulusi wotsika ndikukula mu nkhani yomaliza ya jakisoni, zomwe zimawonjezera modlus.

(3) Madzi otsika madzi

Ubwinowu makamaka ndi pa. Pankhani yamadzimadzi, odzaza ndi PPS ndi ofanana; Ndipo pamakina, pa compaostites yokhala ndi kuchuluka komweko kuli kokulirapo. Zotsatira zake ndikuti kufooka kwa ma pps chifukwa cha kuchepa kwa madzi kumachepetsa zinthu zambiri kuposa zomwe zimapangidwa ndi zinthu zomwezo.

(4) mawonekedwe apadera azitsulo ndi kuuma kwakukulu

Kudzera mu kuphatikiza kwa nkhungu zapadera ndi kutentha kwamphamvu kwamphamvu kumapangitsanso mawu ofanana ndi kugunda kwa manja a anthu, ndipo pamwamba amakhala osalala ngati kalilore.

Peek ali ndi katundu woterewu:

(1) Kuzunza kwambiri.

Itha kugwiritsidwa ntchito kwa nthawi yayitali pa 250 ° C, kutentha kumatha kufikira 300 ° C pompopompo, ndipo sikuwongolera nthawi yochepa kwambiri mpaka 400 ° C.

(2) katundu wamakina abwino komanso mawonekedwe osakhazikika.

Peek imatha kukhala ndi mphamvu kwambiri pa kutentha kwambiri. Mphamvu zowerama pa 200 ° C zitha kufikira pa 3 pa 3 Mpamba, ndipo zolimba zamphamvu ndikulimba pa 250 ° C ikhoza kufikira 12-13 MPA. Ndioyenera kwambiri kupanga zinthu zosapitilira kutentha kwambiri. Zogwirira Ntchito. Peek ali ndi mphamvu zambiri, kukhazikika kwabwino komanso kogwirizana kokwanira kwa kukula kwa mzere, komwe kumayandikira kwambiri ndi zitsulo zitsulo. Kuphatikiza apo, peek alinso kukana kwabwino, kumatha kupirira kupsinjika kwakukulu mukakhala muutumiki, ndipo sikungapangitse kuwonjezera chifukwa chowonjezera nthawi.

(3) Kukaniza kwamphamvu kwamankhwala.

Peek amaletsa mankhwala ambiri mankhwala ambiri, ngakhale kutentha kwambiri, ndikutsutsana kwambiri ndi zitsamba za nickel. Nthawi zambiri, chinthu chokhacho chomwe chingasungunuke cha peek chimakhazikika pa sulfuric acid.

(4) Zabwino hydrolysis.

Kugonjetsedwa ndi kuwonongeka kwa mankhwala ndi madzi kapena mpweya wambiri wamadzi. Pansi pa mikhalidwe ya kutentha kwambiri komanso kukakamizidwa kwambiri, zigawo zikuluzikulu za peek kumatha kugwira ntchito mosalekeza m'madzi a madzi ndikusungabe mphamvu zabwino. Monga kumiza madzi mopitirira 100 ° C kwa masiku 200, mphamvu zake sizinasinthe.

(5) Zabwino kwambiri.

Itha kufikira ul 94 V-0 v-0 v-0 v-0, ndikudzitchinjiriza, ndikupanga utsi wocheperako komanso mpweya woopsa pansi pamakhalidwe.

(6) Magetsi abwino.

Peek amasunga katundu wamagetsi pazinthu zambiri komanso kutentha.

(7) Kulimbana ndi ma radiation.

Peek ali ndi kapangidwe kake kokhazikika, ndipo magawo a peek amatha kugwira ntchito bwino pansi pa Mlingo wambiri wa radiation.

(8) Kulimba mtima kwabwino.

Kuletsa kutopa kuti musinthe kupsinjika ndizabwino kwambiri kwa mapulatipi onse ndipo akufanana ndi owongolera.

(9) Chingwe chabwino kwambiri komanso kuvala kukana.

Kuvala Kwambiri Kukana ndi kulumikizana kochepa kwa mikangano kumasungidwa pa 250 ° C.

(10) Kuchita bwino.

Kutukuka kosavuta ndi jakisoni kumaumba, komanso luso laumba lamphamvu.

Post Nthawi: 01-09-22