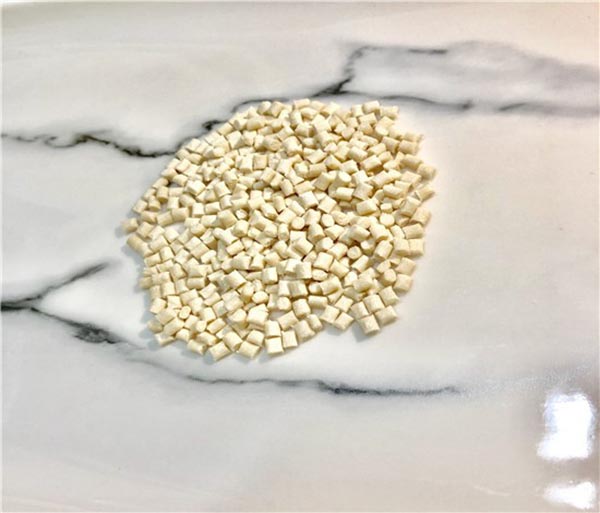

PPO

Kuchita kwa PPO

Polyphenylether ndi poly2, 6-dimethyl-1, 4-phenylether, yomwe imadziwikanso kuti polyphenyloxy, Polyphenyleneoxiole (PPO), yosinthidwa polyphenylether imasinthidwa ndi polystyrene kapena ma polima ena (MPPO).

PPO ndi mtundu wa pulasitiki uinjiniya ndi ntchito bwino mabuku, kuuma apamwamba kuposa PA, POM, PC, mkulu makina mphamvu, kukhazikika bwino, kutentha kukana (matenthedwe mapindikidwe kutentha kwa 126 ℃), mkulu dimensional bata (shrinkage mlingo wa 0,6%) , mlingo wochepa wa kuyamwa madzi (osakwana 0.1%). Choyipa ndichakuti UV ndi wosakhazikika, mtengo wake ndi wokwera komanso kuchuluka kwake ndi kochepa. PPO ndi yopanda poizoni, yowonekera, yocheperako pang'ono, yokhala ndi mphamvu zamakina, kukana kumasuka, kukana kugwa, kukana kutentha, kukana madzi, kukana kwa nthunzi wamadzi.

Mu osiyanasiyana kutentha, pafupipafupi zosiyanasiyana ntchito zabwino magetsi, palibe hydrolysis, kupanga shrinkage mlingo ndi yaing'ono, kuyaka ndi kudzikonda flameout, kukana asidi inorganic, zamchere, onunkhira hydrocarbon kukana, halogenated hydrocarbon, mafuta ndi zina osauka ntchito, Kutupa kosavuta kapena kusweka kwa nkhawa, chotsalira chachikulu ndikusungunuka kwamadzimadzi, kukonza ndi kupanga zovuta, ntchito zambiri zothandiza za MPPO (PPO blend kapena alloy).

Zotsatira za PPO

PPO ili ndi kukhuthala kwamphamvu kwambiri, kusayenda bwino kwamadzi komanso kuwongolera kwambiri. Musanayambe kukonza, m'pofunika kuumitsa kwa maola 1-2 pa kutentha kwa 100-120 ℃, kupanga kutentha ndi 270-320 ℃, kutentha kwa nkhungu ndi koyenera pa 75-95 ℃, ndikupanga processing pansi pa "high kutentha, kuthamanga kwambiri komanso kuthamanga kwambiri”. Popanga mowa wapulasitiki uwu, mawonekedwe a jet flow (mtundu wa njoka) ndiwosavuta kupangidwa kutsogolo kwa mphuno, ndipo njira yotuluka ndi yabwinoko.

Makulidwe ocheperako amachokera ku 0.060 mpaka 0.125 mainchesi pamagawo owumbidwa wamba ndi mainchesi 0.125 mpaka 0.250 pamagawo a thovu. Kutentha kumayambira UL94 HB mpaka VO.

Mtundu wofananira wa ntchito

PPO ndi MPPO amagwiritsidwa ntchito makamaka pazida zamagetsi, magalimoto, zida zapakhomo, zida zamaofesi ndi makina opanga mafakitale, ndi zina zambiri, pogwiritsa ntchito kukana kutentha kwa MPPO, kukana kukhudzidwa, kukhazikika kwazithunzi, kukana kwa abrasion, kukana kuphulika;

PC

Kuchita kwa PC

PC ndi mtundu wa mapulasitiki opanda mawonekedwe, opanda fungo, opanda poizoni, owonekera kwambiri opanda mtundu kapena achikasu pang'ono a thermoplastic engineering, okhala ndi zinthu zabwino kwambiri zakuthupi komanso zamakina, makamaka kukana kwambiri, kulimba kwamphamvu kwambiri, mphamvu yopindika, mphamvu yopindika; Kulimba kwabwino, kutentha kwabwino komanso kukana nyengo, mitundu yosavuta, kuyamwa kwamadzi otsika.

Kutentha kwa kutentha kwa PC ndi 135-143 ℃, zokwawa ndizochepa ndipo kukula kwake ndi kokhazikika. Ili ndi kutentha kwabwino komanso kukana kutentha kwapansi, kukhazikika kwamakina, kukhazikika kwapang'onopang'ono, mphamvu zamagetsi ndi zoletsa moto pakutentha kwakukulu. Itha kugwiritsidwa ntchito kwa nthawi yayitali -60 ~ 120 ℃.

Wokhazikika pakuwala, koma osagonjetsedwa ndi kuwala kwa UV, kukana kwanyengo yabwino; Kukana kwa mafuta, kukana kwa asidi, kukana kwa alkali, asidi oxidation ndi amine, ketone, kusungunuka mu ma hydrocarboni a chlorinated ndi zosungunulira zonunkhira, kuletsa mawonekedwe a bakiteriya, mawonekedwe oletsa moto ndi kukana kuipitsidwa, nthawi yayitali m'madzi yosavuta kuyambitsa hydrolysis ndi kusweka, kuipa kwake ndi chifukwa cha kuchepa kwamphamvu kwa kutopa, kosavuta kutulutsa kupsinjika kwapang'onopang'ono, kukana zosungunulira, kusayenda bwino kwamadzi, kusamva bwino kukana. PC jakisoni akamaumba, extrusion, akamaumba, kuwomba akamaumba, kusindikiza, kugwirizana, ❖ kuyanika ndi Machining, njira yofunika kwambiri processing ndi jekeseni akamaumba.

Zotsatira za PC

Zinthu za PC zimakhudzidwa kwambiri ndi kutentha, kusungunuka kwake kusungunuka ndi kuwonjezeka kwa kutentha ndi kuchepetsedwa kwambiri, kuthamanga mofulumira, osakhudzidwa ndi kukakamizidwa, kuti apititse patsogolo madzi ake, kutenga njira yowotchera. PC zinthu pamaso processing kuti ziume mokwanira (120 ℃, 3 ~ 4 maola), chinyezi ayenera kulamulidwa mkati 0.02%, kufufuza madzi processing pa kutentha adzapanga mankhwala kubala turbidious mtundu, siliva ndi thovu, PC firiji ali ndi mphamvu ndithu. kukakamiza mkulu zotanuka deformation. Kulimba kwamphamvu kwambiri, kotero kumatha kukhala kukanikiza kozizira, kujambula kozizira, kukanikiza kozizira ndi njira zina zozizira. Zinthu za PC ziyenera kuumbidwa pansi pazikhalidwe za kutentha kwakukulu, kutentha kwa nkhungu ndi kuthamanga kwambiri komanso liwiro lotsika. Kwa sprue ang'onoang'ono, jakisoni wothamanga kwambiri ayenera kugwiritsidwa ntchito. Kwa mitundu ina ya sprue, jakisoni wothamanga kwambiri ayenera kugwiritsidwa ntchito.

Kuwongolera kutentha kwa nkhungu mu 80-110 ℃ kuli bwino, kupanga kutentha mu 280-320 ℃ ndikoyenera.

Mtundu wofananira wa ntchito

Magawo atatu ogwiritsira ntchito PC ndi makampani opanga magalasi, mafakitale agalimoto ndi zamagetsi, mafakitale amagetsi, zotsatiridwa ndi zida zamakina, ma disc owoneka, zovala za anthu wamba, makompyuta ndi zida zina zamaofesi, chithandizo chamankhwala ndi thanzi, filimu, zosangalatsa ndi zida zodzitetezera.

Mtengo PBT

Kuchita kwa PBT

PBT ndi imodzi mwazinthu zolimba kwambiri za engineering thermoplastic, ndi semi-crystalline material, imakhala ndi kukhazikika kwamankhwala kwabwino kwambiri, mphamvu zamakina, mawonekedwe amagetsi amagetsi komanso kukhazikika kwamafuta. Zidazi zimakhala ndi kukhazikika kwabwino mumitundu yosiyanasiyana ya chilengedwe, ndipo mawonekedwe a PBT amayamwa chinyezi ndi ofooka kwambiri.

Malo osungunuka (225% ℃) ndi kutentha kwakukulu kwa kutentha kumakhala kotsika kuposa zinthu za PET. Kutentha kwa Veka kufewetsa ndi pafupifupi 170 ℃. Kutentha kwa kusintha kwa galasi kuli pakati pa 22 ℃ ndi 43 ℃.

Chifukwa cha kuchuluka kwa crystallization ya PBT, kukhuthala kwake ndikotsika kwambiri, ndipo nthawi yozungulira ya magawo apulasitiki nthawi zambiri imakhala yotsika.

Zotsatira za PBT

Kuyanika: Izi zimasungunuka mosavuta pa kutentha kwakukulu, kotero ndikofunikira kuziwumitsa musanazikonze. Kuwumitsa koyenera mumlengalenga ndi 120C, 6-8 hours, kapena 150 ℃, 2-4 hours. Chinyezi sayenera kupitirira 0.03%. Ngati mukugwiritsa ntchito chowumitsira hygroscopic, kuyanika koyenera ndi 150 ° C kwa maola 2.5. The processing kutentha ndi 225 ~ 275 ℃, ndi kutentha analimbikitsa ndi 250 ℃. Pakuti unenhanced zinthu nkhungu kutentha ndi 40 ~ 60 ℃.

Malo ozizira a nkhungu ayenera kukonzedwa bwino kuti achepetse kupindika kwa zigawo zapulasitiki. Kutentha kuyenera kutayika mwachangu komanso mofanana. Ndibwino kuti m'mimba mwake wa nkhungu kuzirala patsekeke ndi 12mm. Kuthamanga kwa jakisoni kumakhala kochepa (mpaka 1500bar maximum), ndipo mlingo wa jakisoni uyenera kukhala wothamanga kwambiri (chifukwa PBT imalimba mwamsanga).

Wothamanga ndi chipata: Wothamanga wozungulira akulimbikitsidwa kuti awonjezere kusamutsa kuthamanga.

Mtundu wofananira wa ntchito

Zipangizo zapakhomo (masamba opangira chakudya, zotsukira, mafani amagetsi, nyumba zowumitsira tsitsi, ziwiya za khofi, ndi zina), zida zamagetsi (ma switch, nyumba zamagetsi, mabokosi a fuse, makiyi a kiyibodi apakompyuta, ndi zina zambiri), makampani amagalimoto (magalasi owunikira, mapanelo a thupi, zotchingira magudumu, zitseko ndi mazenera zigawo, etc.

Nthawi yotumiza: 18-11-22