Pi (Polymide) ufa, ndodo, pepala, zinthu za CNC

Thermosetting polyamides amadziwika ndi matenthedwe, kugwiritsa ntchito mankhwala abwino, katundu wabwino kwambiri, komanso mawonekedwe a lalanje / wachikaso. Ma polyamides adapangidwa ndi graphite kapena kukonzekera mapira agalasi amasintha mphamvu mpaka 340 MPA (49,000 PPA) ya 21,000 MPA (3,000,000 pla). Thermones polymer Matrix ma polyamideides akuwonetsa zotsika kwambiri komanso mphamvu yayikulu. Izi zimasungidwa nthawi yopitilira kutentha kwa kutentha kwa 232 ° C (450 ° F) komanso maphwando afupi, okwera 704 ° F). [1,299 ° F). [1,299 ° F). [1,299 ° F). [1,299 Magawo owumbidwa ndi ma polymide owumbidwa ndi a lamiko amakhala ndi pokana kutentha. Kutentha kokhazikika kwa magawo oterowo kumayiko ndi kumazirana kumasiyanasiyana kwa ochulukirapo 260 ° C (500 ° F). Ma polimaides nawonso amagonjetsedwanso kuti agwirizane ndi kuyankha kwamphamvu ndipo nthawi zambiri sayenera kusakanikirana ndi lala wamoto. Ambiri amanyamula mtengo wa vtm-0. Polymide angminide amakhala ndi vuto la flexum pa 249 ° C (480 ° F) ya maola 400.

Magawo wamba a Polymide sakhudzidwa ndi mafuta omwe nthawi zambiri amagwiritsa ntchito ma sol sol - kuphatikizapo ma hydrocarbons, ma etter, alent, mowa ndi zoledzera. Amathanso kufooka koma osavomerezeka kuti agwiritse ntchito madera omwe ali ndi alkalis kapena itorganic acid. Ma poryamides ena, monga CP1 ndi Trin XLS, ndi zosungunulira-soluble ndikuwonetsa kumveka bwino. Zosasinthika zosungunuka zimawapangitsa kuti atulutsire ndi kutentha kochepa.

Zovala za Pi

Pi ndi lala lake loyaka, lomwe silimawotcha kutentha kwambiri

Makina amakampani otsika kutentha kwa kutentha

Nkhaniyi ili ndi luso labwino kwambiri lokongoletsa, imatha kukwaniritsa zofunika zosiyanasiyana zofananira

Ntchito zabwino kwambiri: kutentha kwambiri komanso kutentha kwakanthawi

Kuchita bwino kwa magetsi: Kusunga kwamagetsi

PI wamkulu wa PI

Zogwiritsidwa ntchito kwambiri m'makina, zigawo, zigawo zamagetsi, zamagetsi ndi zamagetsi, njanji, zojambula zamasewera, ma tayi amafuta, zinthu zamafuta.

Zipangizo zopepuka ndi zopepuka, zosinthika, zosagwirizana ndi kutentha ndi mankhwala. Chifukwa chake, amagwiritsidwa ntchito pakompyuta zamagetsi zosinthasintha komanso ngati filimu yolowera pa waya wamatsenga. Mwachitsanzo, mu kompyuta ya laputopu, chingwe chomwe chimalumikiza bolodi yayikulu kuwonetsa (chomwe chikuyenera kusintha nthawi iliyonse laputopu? Zitsanzo za mafilimu a Polylimide zimaphatikizapo apical, Kaptun, UPailex, Vecc PO, Norton Th ndi Kaptrex.

Kugwiritsa ntchito kowonjezera kwa polymide utoto kumakhala ngati kolowera komanso kusanjikiza popanga madera ophatikizidwa ndi ma mems. Zigawo za Polymide zimakhala ndi mphamvu zabwino komanso mphamvu zowoneka bwino, zomwe zimathandizanso kutsatsa pakati pa zigawo za polymide kapena pakati pa kusanjikiza chitsulo.

| Bwalo | Milandu |

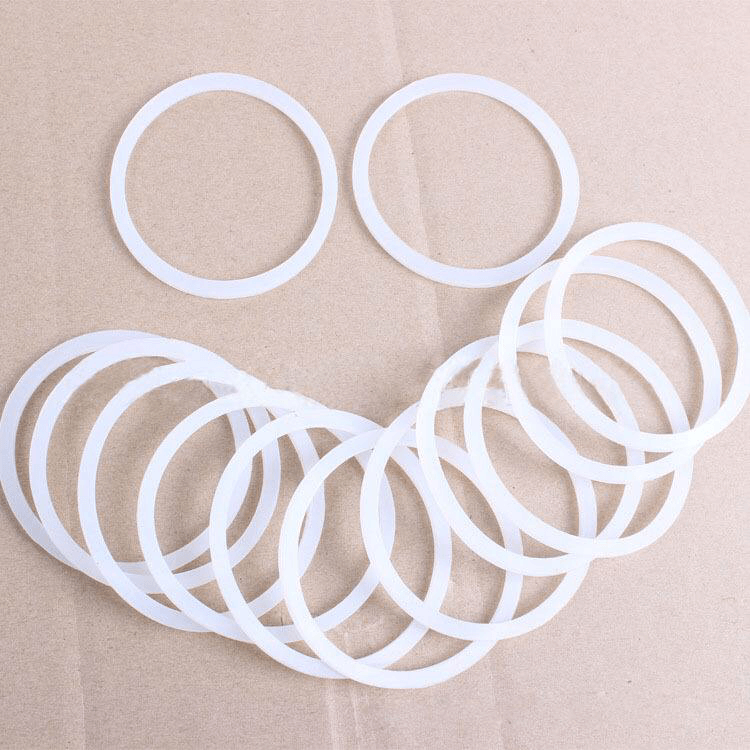

| Gawo la Makampani | Kutentha kwakukulu komwe kumadzipangira mafuta, mphete ya comprescer mphete, mphete yosindikizira |

| Zovala zamagetsi | Ma radiators, okonda ozizira, chogwirira chitseko, thanki ya mafuta, mpweya wa mpweya, chivundikiro cha madzi |

Spla-3d Maphunziro ndi Mafotokozedwe

| Giledi | Kaonekeswe |

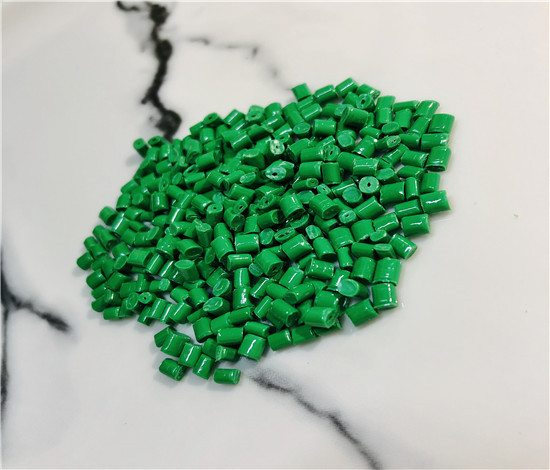

| Spla-3d101 | Pulogalamu yayitali kwambiri. Maakaunti oposa 90%. Kusindikiza kwabwino kwa ndi kukula kwamphamvu. Ubwino ndi wokhazikika, kusindikiza kosalala komanso katundu wabwino. |

| Spla-3dc102 | Nkhani za 50-70% ndipo zimadzazidwa makamaka ndikuzizwa. Ubwino wabwino wopanga, kusindikiza kosalala kwa masitepe makina. |